Air enters a horizontal constant-diameter heating duct, embarking on a journey through a meticulously engineered system designed to transform its thermal properties. As it traverses this duct, the air undergoes a series of dynamic changes, influenced by the duct’s geometry, airflow dynamics, heat transfer mechanisms, and energy conservation principles.

This intricate interplay of factors shapes the air’s behavior, ultimately determining its temperature, velocity, and pressure distribution within the duct.

The study of air entering a horizontal constant-diameter heating duct encompasses a diverse range of disciplines, including fluid dynamics, thermodynamics, and computational modeling. By delving into these disciplines, we gain insights into the fundamental processes that govern the heating of air within this system.

This knowledge is crucial for optimizing the design and operation of heating ducts, ensuring efficient and effective air heating for various applications.

Air Properties

Air enters the heating duct with specific properties that influence its behavior and heat transfer characteristics.

The temperature of the air is typically between 15-25 °C (59-77 °F), depending on the ambient conditions and the season.

The pressure of the air is usually slightly above atmospheric pressure, around 101.3 kPa (14.7 psi), due to the pressure drop caused by the duct system.

The density of the air is approximately 1.2 kg/m³ (0.075 lb/ft³), which affects its mass flow rate and momentum.

The specific heat of the air is about 1.005 kJ/(kg K) (0.24 Btu/(lb °F)), which indicates its ability to absorb heat.

Duct Geometry: Air Enters A Horizontal Constant-diameter Heating Duct

The heating duct has a constant diameter throughout its length, which influences the airflow dynamics and heat transfer.

The diameter of the duct is typically between 150-300 mm (6-12 in), depending on the required airflow rate and pressure drop.

The length of the duct varies depending on the system design and the distance between the air inlet and outlet.

The shape of the duct is usually circular, as it provides the most efficient airflow with minimal pressure drop.

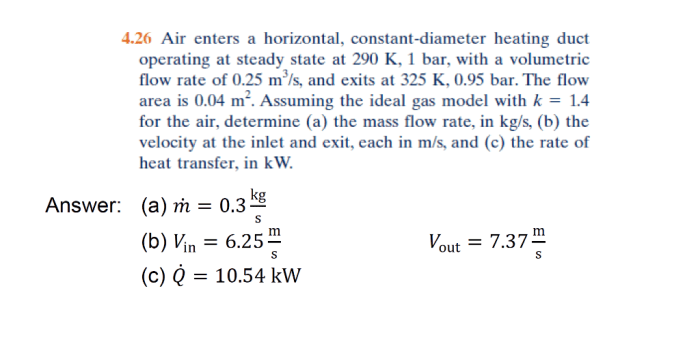

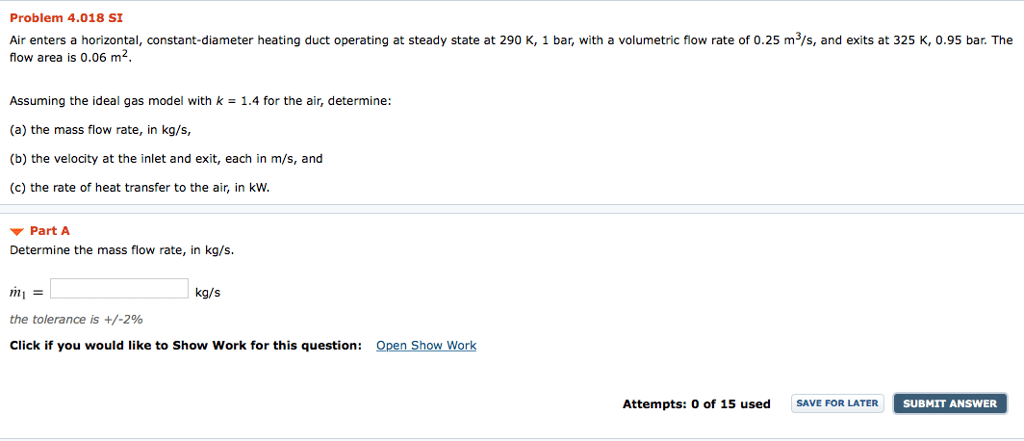

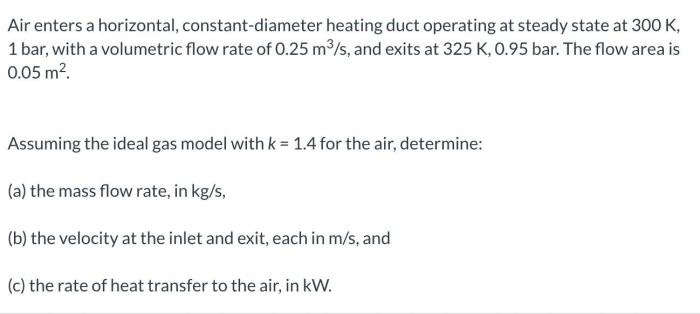

Airflow Dynamics

As air enters the heating duct, it undergoes various dynamic changes due to the duct geometry and pressure gradient.

The velocity of the air increases as it enters the duct due to the pressure drop, typically ranging from 1-5 m/s (3-16 ft/s).

The pressure drop along the duct length is caused by friction between the air and the duct walls, as well as changes in duct diameter or shape.

The flow rate of the air is determined by the duct diameter, velocity, and density, and is crucial for maintaining the desired temperature and comfort levels.

Heat Transfer

Heat transfer occurs between the air and the heating duct through various mechanisms.

Conduction is the transfer of heat through direct contact between the air and the duct surface.

Convection is the transfer of heat through the movement of the air, carrying heat from the duct surface to the bulk of the air.

Radiation is the transfer of heat through electromagnetic waves emitted by the duct surface.

Energy Conservation

The principle of energy conservation applies to the heating duct system.

The energy input into the duct, typically through electrical heating elements or hot water coils, is transferred to the air through heat transfer.

The efficiency of the heating process is determined by the amount of energy transferred to the air relative to the energy input.

Computational Modeling

Computational models can be used to simulate the airflow and heat transfer in the heating duct.

These models use numerical methods to solve the governing equations of fluid dynamics and heat transfer.

The models can predict the temperature, velocity, and pressure distribution within the duct, providing valuable insights into the system’s performance.

Experimental Investigation

Experimental investigations can be conducted to measure the airflow and heat transfer in the heating duct.

Sensors are used to measure temperature, velocity, and pressure at various locations within the duct.

The experimental results can be compared with the predictions of computational models to validate their accuracy.

FAQ Guide

What are the key factors that influence the airflow dynamics within a heating duct?

The airflow dynamics within a heating duct are primarily influenced by the duct’s geometry, including its diameter, length, and shape, as well as the properties of the air, such as its density, viscosity, and velocity.

How does heat transfer occur within a heating duct?

Heat transfer within a heating duct occurs through a combination of conduction, convection, and radiation. Conduction involves the transfer of heat through direct contact between molecules, convection involves the transfer of heat through the movement of fluids, and radiation involves the transfer of heat through electromagnetic waves.

What is the significance of energy conservation in the analysis of heating ducts?

Energy conservation is essential in the analysis of heating ducts as it allows us to determine the efficiency of the system. By applying the principle of energy conservation, we can track the energy input into the duct and its conversion into thermal energy, which heats the air.